GSB-78®

P-608-R Rapid Cure &

UFGS 32 01 13.63 compliant

Nighttime applications & enhanced shelf life.

HARNESSing SUPERIOR CHEMISTRy

GSB-78®

P-608-r Rapid Cure

UFGS 32 01 13.63

NIGHTTIME APPLICATIONS & Good performance for 5 years

GSB-78® is a solvent-based, Gilsonite-modified, asphalt pavement preservation treatment. Unlike a water-based asphalt emulsion, GSB-78® cures via a chemical process which does not require sunshine or other climatic influences.

Oxidation ruins asphalt pavement binder. Our unique GSB chemistry slows the molecular aging and deterioration reactions in pavement binder oils, so it keeps the binder healthy.

FEATURES

35% gilsonite

For short-window or nighttime applications

One-pass treatment

SIGNIFICANTLY DELAY

COSTLY REHABILITATION

GET MORE YEARS OF USEFUL LIFE FROM OLD pavements without sacrificing safety or quality

GSB Products are compliant with FAA specifications and recommended for runway applications because they don’t “slide” when it comes to friction performance. Safety is the first priority on any airfield project, especially when runways are involved. GSB Products safely preserve hundreds of runways around the world.

P-608-R

UFGS 32 01 13.64

AVOID AIRPORT CLOSURES

ASI allows busy airports to maintain revenue-producing productivity and military airfields to maintain a high state of readiness

There’s no another preservation treatment servicing the aviation industry that allows busy airports to maintain revenue-producing productivity and military airfields to maintain a high state of readiness.

Grand Juction (GJT) Airport Case study

In 2016, Grand Junction airport did not want to close their main runway for several days and lose ops.

So, Armstrong Engineering, with collaboration from ASI, designed a nighttime project with 6-hours working windows for the contractor. This was one of the first pavement preservation seal coat projects in the US executed at night.

A segment of the pavement was treated at 11:00pm (i.e., the treatment was applied, cured, passed friction testing requirements, temporary striping applied). And that same segment of pavement was back open for traffic by 5:00am the next morning.

GJT was so happy with the treatment, it retreated with P-608-R (GSB-78®) again in fall of 2021.

WE’VE GOT

YOU COVERED

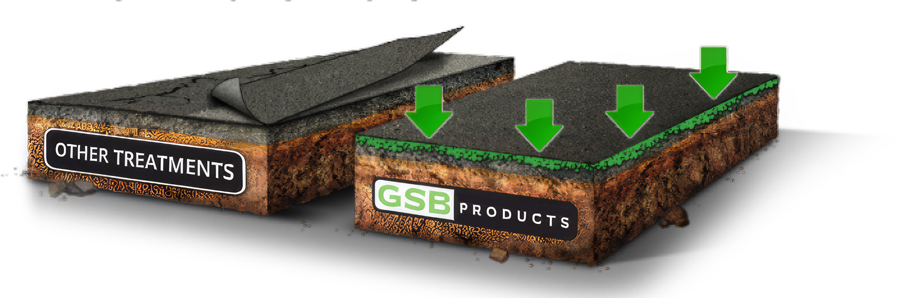

There are two things a surface treatment can do to extend the service life of an asphalt pavement:

Penetrate to enhance it from the inside, or seal to protect it from the outside. Most surface treatments do one thing, but GSB Products do both:

integrates to restore

GSB integrates into the pavement and becomes part of the surface matrix to restore, restructure, strengthen, and protect the aging pavement. Other treatments sit on the pavement surface and may crack, peel (delaminate), or wear off.

Seals to protect

GSB also provides a durable, UV-proof, and waterproof seal, protecting the asphalt binder.

GSB-78® has been used successfully

on roads and airfields around the

world for more than 40 years

Massive ROI

Achievable

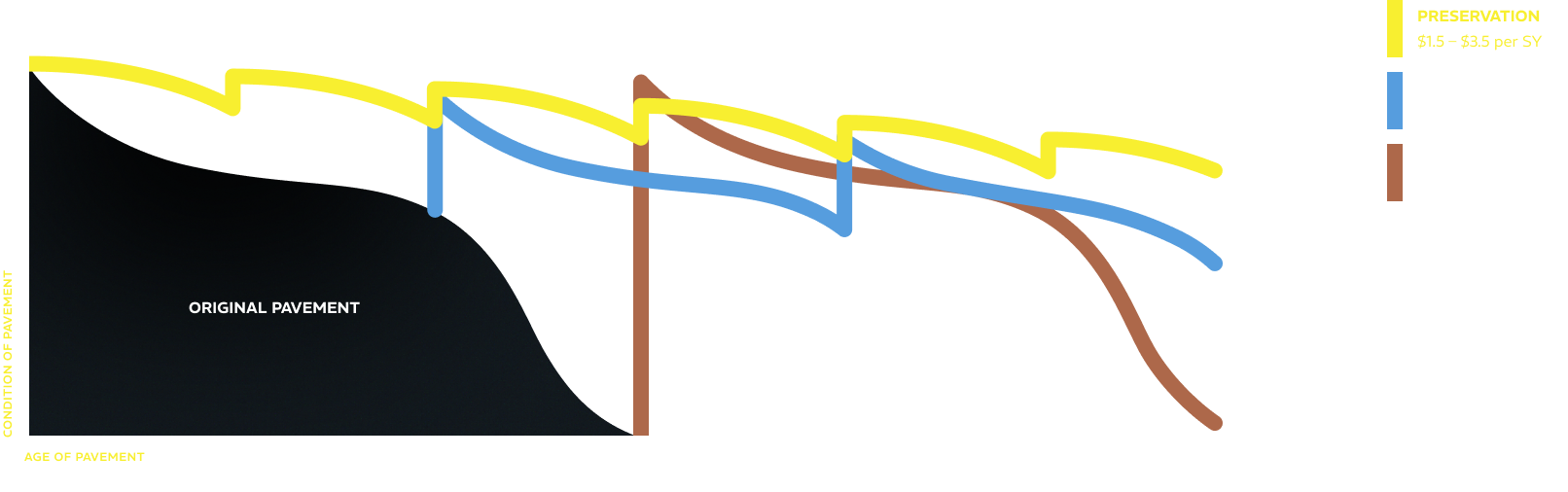

Multiple longitudinal studies have demonstrated that road asphalt pavements with high-quality surface treatments, when applied early in the pavement life and with regular reapplications, will maintain significantly higher PCI values than unmaintained pavements.

It is essential that cost-effective interventions – such as the application of proven GSB products – are made early and often to mitigate surface oxidization.

As much as 60% of the life of the pavement can be lost to oxidation in the first two years.

Pavement Preservation Council

FAA Pavement Management Program

AC № 150/5380-78, Page 4

GSB Products are compliant with FAA specifications and recommended for runway applications because they don’t “slide” when it comes to friction performance. Safety is the first priority on any airfield project, especially when runways are involved. GSB Products safely preserve hundreds of runways around the world.

By applying GSB products in the initial life of the pavement (even as part of the construction process), and making timely reapplications (about every 5 years), a pavement’s useful life can be cost-effectively extended to a significant degree.

We have known about the benefit of preserving the oils and resin in our wooden structures with stains and other preservatives. They protect against the detrimental effects of surface oxidation (e.g., rapid aging and cracking).

A similar deterioration process occurs with the loss of oils and resins critical to extending asphalt pavement life.