Preserve Airfields

Keep New Pavements

Good

GSB-88®

FAA P-608 &

UFGS 32 01 13.63

compliant

The original emulsion-based restorative and protective sealer brought to market in 1988

GSB-88® and GSB-88-HEAVY™ are cationic, gilsonite-modified asphalt emulsions.

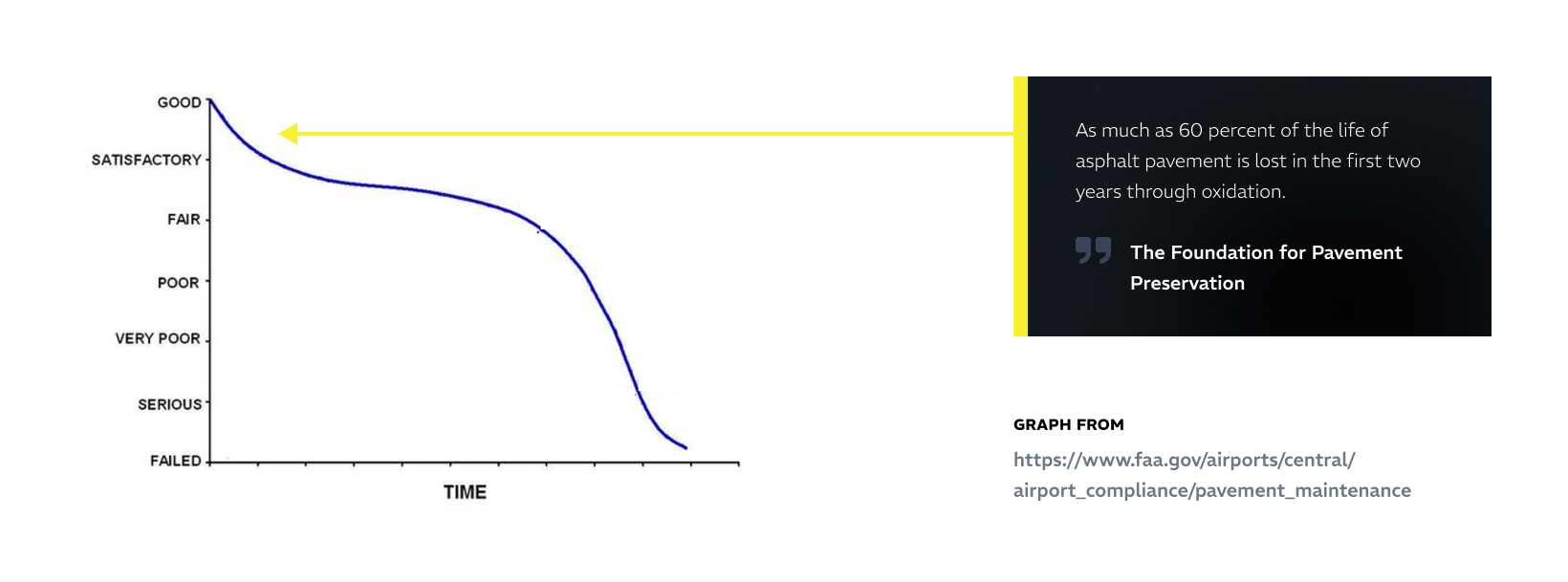

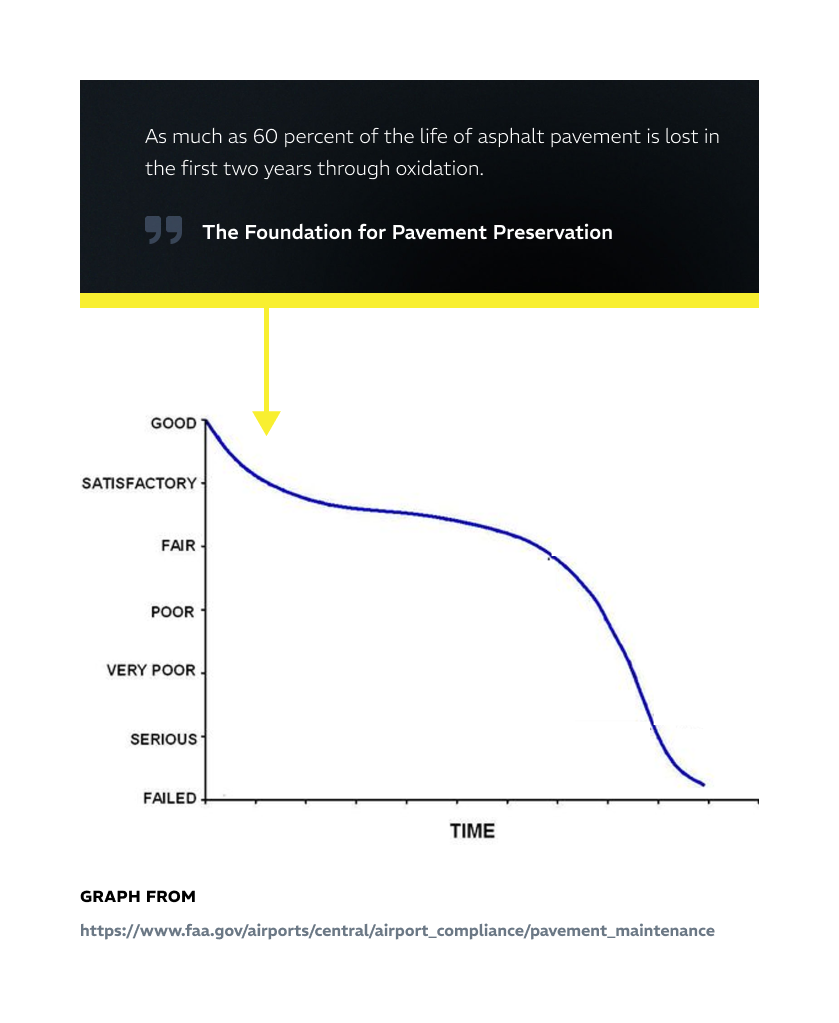

FAA and military pavement experts project that as much as 90% of airfield asphalt pavement deterioration can be attributed to surface oxidation. Early application and timely reapplications (about every five years) of GSB Products can mitigate surface oxidation as a contributing factor in airfield asphalt deterioration.

FAA P-608

UFGS 32 01 13.63

Keep Good

Pavements Good

FAA P-608

UFGS 32 01 13.63

FAA P-608-R

UFGS 32 01 13.64

P608H

Extend pavement service life by restoring and protecting the pavement surface

A 27-YR-OLD PAVEMENT AT EXTREME ELEVATION

Only GSB-88® has been used, and the 4th (most recent) application was 2020. PCI ratings from the State Aero website show the condition of this pavement (constructed in 1995) over time and the impact FAA P-608 applications had on PCI:

2012 PCI 77

2015 PCI 87

2018 PCI 84

2021 PCI 87

AVOID AIRPORT CLOSURES

GSB-78® / FAA P-608-r

RESTORATIVE AND PROTECTIVE Seal Coat THAT CAN BE APPLIED AT NIGHT

GSB-78® is a gilsonite-modified asphalt rapid-cure cutback chemically engineered using gilsonite ore and specially selected asphalt cement (AC) and diluents. Unlike a water-based asphalt emulsion, GSB-78® cures via a chemical process which does not require sunshine or other climatic influences.

FAA P-608-R

UFGS 32 01 13.64

ASI allows busy airports to maintain revenue-producing productivity and military airfields to maintain a high state of readiness.

Grand Junction (GJT) airport

Grand Junction (GJT) airport

Main runway was treated at night,

so no lost travel days.

And the treatment performed well for 5 years.

In 2016, Grand Junction airport did not want to close their main runway for several days and lose ops.

So, Armstrong Engineering, with collaboration from ASI, designed a nighttime project with 6-hours working windows for the contractor. This was one of the first pavement preservation seal coat projects in the US executed at night.

A segment of the pavement was treated at 11:00pm (i.e., the treatment was applied, cured, passed friction testing requirements, temporary striping applied). And that same segment of pavement was back open for traffic by 5:00am the next morning.